There are two main types of capacitors used on printed circuit boards (PCB), Multi-layer Ceramic Capacitors (MLCC) and electrolytic capacitors. Today we mainly talk about electrolytic capacitors.

The capacitance per unit volume of electrolytic capacitors is very large, tens to hundreds of times larger than other types of capacitors; the rated capacity can be very large, and can easily be tens of thousands of μf or even a few f; and its price is much better than other types, because the components of electrolytic capacitors are common industrial materials, such as aluminum and so on. The equipment for manufacturing electrolytic capacitors is also ordinary industrial equipment, which can be mass-produced at a relatively low cost.

MLCC Multi-layer Ceramic Capacitors

electrolytic capacitor

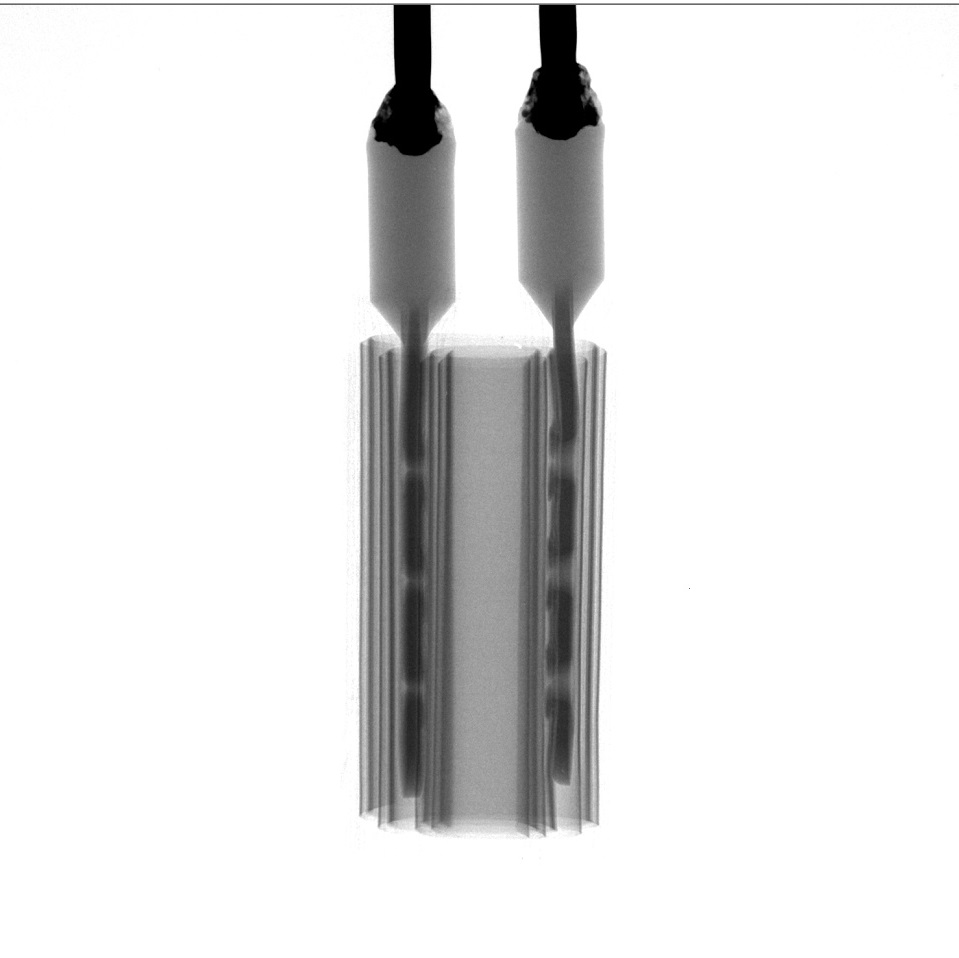

The object rounded by the electrolytic capacitor housing is called element. In the stage before the element is rounded in the housing, there may be undesirable phenomena such as needle height difference, needle bending, and element extrusion. The results of using Wellman X-ray inspection machine are as follows:

Electrolytic capacitor needle height difference

Electrolytic capacitor element extrusion

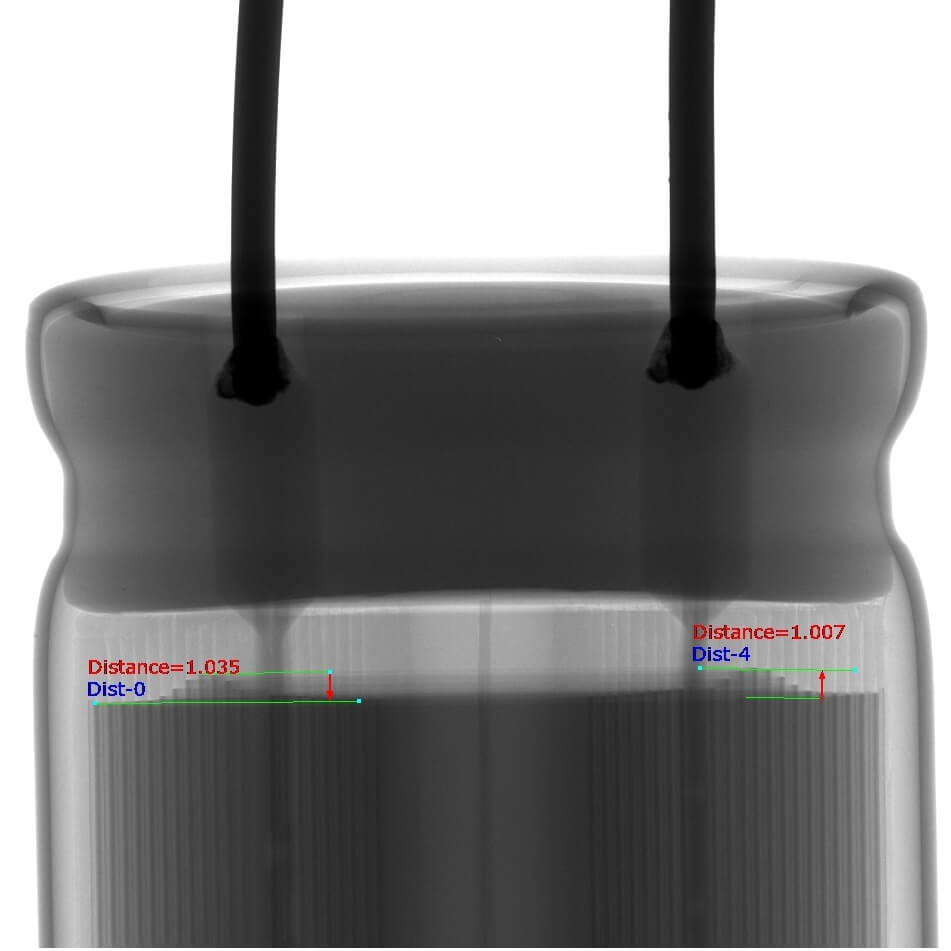

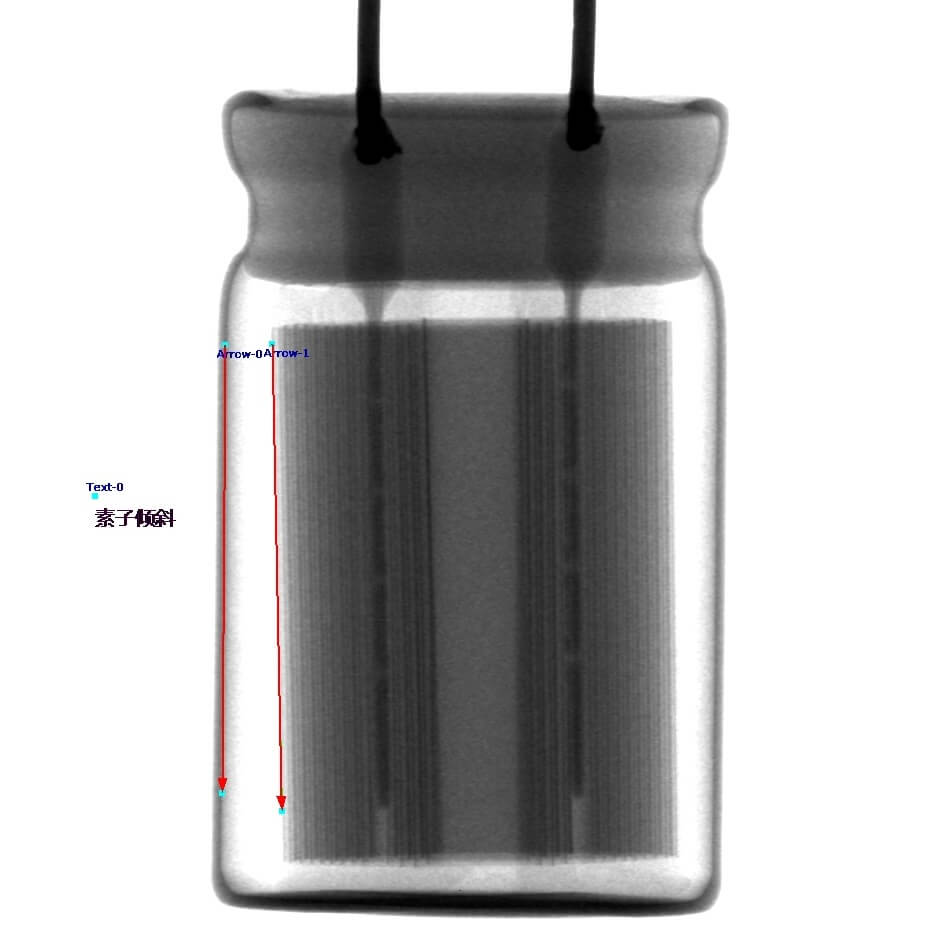

The finished electrolytic capacitors also have defects such as element tilt, edge burr, poor waist (no waist), broken waist, needle bending and other defects. The results of using Wellman X-ray inspection machine are as follows:

Electrolytic capacitor element tilt

Electrolytic capacitor needle bending

Of course, not all undesirable phenomena are unacceptable. Different manufacturers have different quality standards. For example, one of the customers of Wellman Photoelectricity has the following standards: the needle is just slightly bent, the height difference between two needles does not exceed 0.2mm, and the element extrusion does not exceed the corresponding length, the edge burr is slight, there is a waist with no break, etc., it can be judged as an acceptable product. As shown below:

Accepted (OK) electrolytic capacitor