Skip to contentThe Evolution of Industrial Flat Panel Detectors

wellman2023-12-06T17:35:59+08:00In the realm of modern imaging technology, industrial flat panel detectors have emerged as a groundbreaking innovation, revolutionizing the way we capture and process images in industrial applications. These advanced detectors have paved the way for enhanced efficiency, precision, and versatility in various industries, ranging from aerospace and automotive to medical and manufacturing. In this article, we will delve into the intricacies of industrial flat panel detectors, exploring their functionality, applications, and the pivotal role they play in driving progress across diverse sectors.

Understanding Industrial Flat Panel Detectors

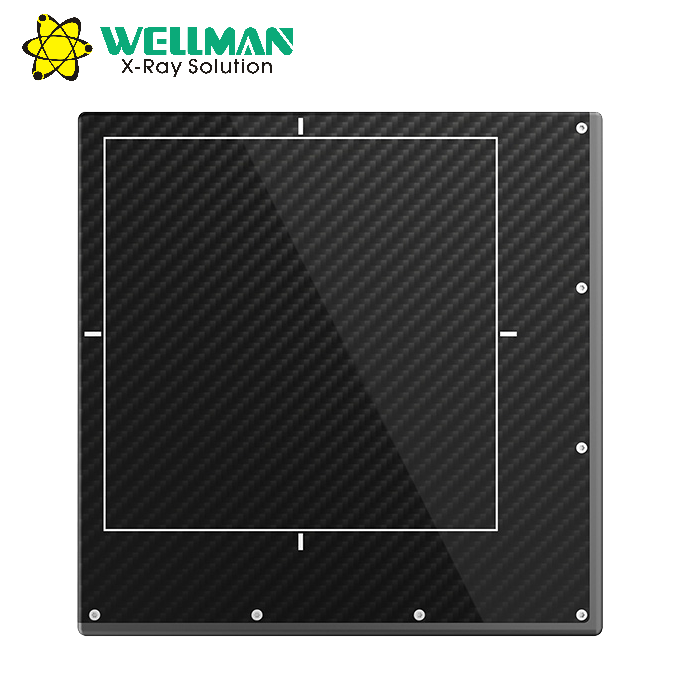

Industrial flat panel detectors are cutting-edge imaging devices that have replaced traditional film-based and computed radiography systems in numerous industrial settings. These detectors are designed to capture high-resolution digital images of objects or materials, utilizing a flat panel composed of a scintillator layer, photodiodes, and thin-film transistors. When exposed to X-rays or other forms of ionizing radiation, the scintillator layer converts the radiation into visible light, which is then detected and converted into digital signals by the photodiodes and transistors.

The Advantages of Industrial Flat Panel Detectors

The transition from conventional imaging methods to industrial flat panel detectors has unlocked a myriad of benefits for industrial applications. One of the most significant advantages is the remarkable improvement in image quality and clarity. These detectors offer superior resolution, contrast, and dynamic range, enabling precise inspection and analysis of intricate details within the captured images. Furthermore, industrial flat panel detectors facilitate rapid image acquisition and processing, leading to enhanced productivity and streamlined workflows in industrial environments.

Applications Across Diverse Industries

The versatility of industrial flat panel detectors has led to their widespread adoption across a spectrum of industries. In the aerospace sector, these detectors are utilized for non-destructive testing (NDT) of aircraft components, ensuring structural integrity and safety. In the automotive industry, industrial flat panel detectors play a pivotal role in quality control and defect detection during the manufacturing process. Moreover, in the medical field, these detectors are instrumental in medical imaging modalities such as digital radiography and fluoroscopy, enabling precise diagnosis and treatment planning.

The Impact on Manufacturing and Quality Assurance

In the realm of manufacturing, industrial flat panel detectors have redefined quality assurance and inspection processes. By providing detailed and accurate imaging capabilities, these detectors enable manufacturers to detect defects, measure dimensions, and assess material properties with unparalleled precision. This, in turn, contributes to the production of high-quality components and products, reducing the likelihood of faulty or substandard items reaching the market. As a result, industrial flat panel detectors have become indispensable tools for ensuring compliance with stringent quality standards and regulations.

The Future of Industrial Flat Panel Detectors

As technology continues to advance, the future of industrial flat panel detectors holds immense promise. Ongoing research and development efforts are focused on further enhancing the performance and capabilities of these detectors, with a particular emphasis on increasing sensitivity, reducing noise, and expanding their applicability to new domains. Additionally, the integration of artificial intelligence and machine learning algorithms with industrial flat panel detectors is poised to revolutionize automated defect recognition and analysis, further optimizing industrial processes and decision-making.

In conclusion, industrial flat panel detectors have ushered in a new era of imaging technology, empowering industries with unprecedented imaging capabilities and efficiency. From their pivotal role in non-destructive testing to their impact on manufacturing and quality assurance, these detectors have become indispensable assets across diverse sectors. As we look to the future, the evolution of industrial flat panel detectors continues to shape the landscape of industrial imaging, driving innovation and progress in the pursuit of excellence.

Share this to your social media