Skip to contentUnderstanding the Distinctions Between Medical and Industrial X-ray Machines

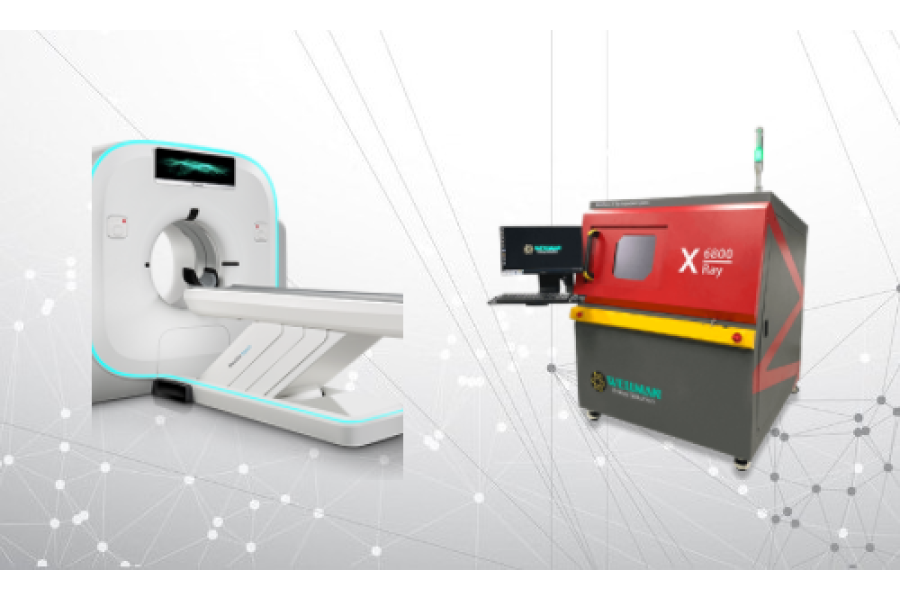

wellman2023-11-27T09:24:08+08:00X-ray technology has revolutionized the fields of medicine and industry, enabling professionals to gain valuable insights into the internal structures of objects and organisms. While both medical and industrial X-ray machines serve the purpose of capturing X-ray images, there are significant differences between the two in terms of design, functionality, and applications. In this article, we will explore the dissimilarities between medical and industrial X-ray machines, shedding light on their unique features and the specific roles they play in their respective domains.

Purpose and Applications:

Medical X-ray Machines: Medical X-ray machines are primarily used in healthcare settings to diagnose and monitor various medical conditions. They are designed to capture detailed images of the human body, aiding in the detection of fractures, tumors, infections, and other abnormalities. Medical X-ray machines are commonly found in hospitals, clinics, and diagnostic centers, where they play a crucial role in guiding medical interventions and treatment plans.

Industrial X-ray Machines: On the other hand, industrial X-ray machines are employed in non-medical settings, primarily for quality control and inspection purposes. These machines are utilized across a wide range of industries, including aerospace, automotive, manufacturing, and electronics. Industrial X-ray machines help identify defects, measure dimensions, and ensure the integrity of materials and products. They are instrumental in detecting flaws in welds, casting, and other manufacturing processes, ensuring compliance with industry standards.

Design and Construction:

Medical X-ray Machines: Medical X-ray machines are designed with patient comfort and safety in mind. They are equipped with features such as adjustable tables, protective shields, and radiation control mechanisms to minimize the patient’s exposure to radiation. These machines are often portable and compact, allowing for easy maneuverability within healthcare facilities. Additionally, medical X-ray machines are equipped with specialized imaging software and tools that enable healthcare professionals to capture high-resolution images with precision.

Industrial X-ray Machines: In contrast, industrial X-ray machines are typically larger and more robust in construction. They are built to withstand harsh industrial environments and are often integrated into production lines or dedicated inspection areas. Industrial X-ray machines employ higher energy levels to penetrate dense materials, such as metals and composites, enabling thorough inspection and analysis. These machines are operated by trained technicians who interpret the X-ray images to identify any defects or anomalies.

Radiation Levels and Safety Measures:

Medical X-ray Machines: Medical X-ray machines are subject to stringent safety regulations to ensure patient safety. The radiation levels emitted by these machines are carefully controlled and kept as low as reasonably achievable. Additionally, lead aprons, collimators, and other protective measures are employed to shield patients and healthcare professionals from unnecessary radiation exposure. Regular maintenance and calibration of medical X-ray machines are essential to ensure accurate and safe imaging.

Industrial X-ray Machines: Industrial X-ray machines, while also adhering to safety guidelines, may operate at higher radiation levels compared to medical X-ray machines. However, strict safety protocols are in place to protect workers and minimize radiation exposure. Industrial X-ray technicians undergo specialized training to handle these machines safely and interpret X-ray images accurately. Shielding materials and controlled access areas are implemented to prevent unauthorized personnel from being exposed to radiation.

Conclusion:

In conclusion, medical and industrial X-ray machines serve distinct purposes and are tailored to meet the specific requirements of their respective fields. Medical X-ray machines are designed for diagnosing and monitoring medical conditions, while industrial X-ray machines are utilized for quality control and inspection in various industries. Understanding the differences between these two types of X-ray machines is crucial for professionals working in healthcare and industrial sectors alike. By recognizing their unique features and applications, we can harness the full potential of X-ray technology to improve patient care and ensure product quality and safety in industrial settings.

Share this to your social media