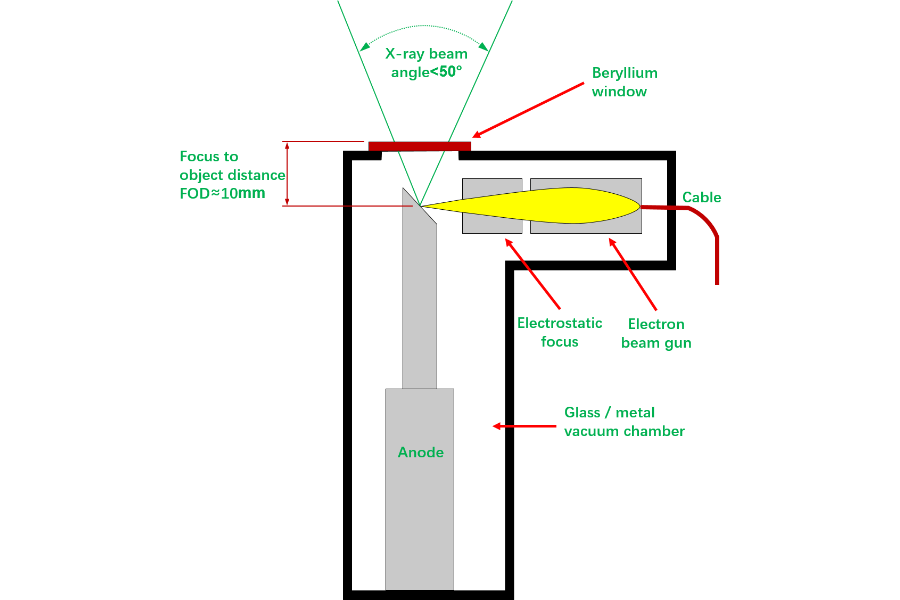

First, the microfocus X-ray tube of WELLMAN X-ray inspection equipment is closed. The microfocus X-ray tubes below 160KV are usually closed.

Accelerating the electrons and hitting a metal target is the easiest way to generate X-rays. After the electron hits the target, 99% of its lost kinetic energy is converted into thermal energy, which causes the target to generate heat; the remaining 1% of the kinetic energy emits photons, generates X-rays.

The closed microfocus X-ray tube also uses this method.

First of all, it is necessary to ensure that space, where the X-rays are generated is in a vacuum state, and the vacuum degree is not lower than 10-4 Pa, to avoid rapid oxidation and burnout of the filament that emits electrons.

The closed X-ray tube is vacuumized during production and then sealed, so that there is no need to vacuumize again, and it can be used after waiting for the low-voltage power supply to heat the filament.

closed microfocus X-ray tube