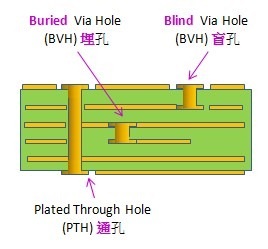

PTH (Plating Through-hole) is a common process on a printed circuit board (PCB), but the surface of the hole drilled directly on the PCB is only resin, which is not conductive. Therefore, we plated a layer of copper on the surface of the drill hole, so that different copper foil layers can conduct electricity.

through-hole

PTH

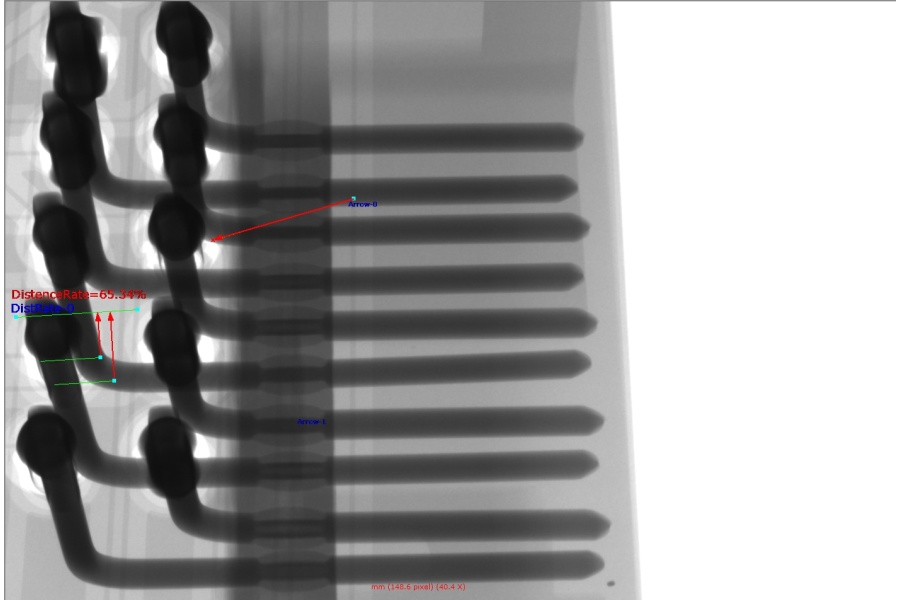

When we insert the pins of the components into the through-holes and then solder the tin into the through-holes by wave soldering machine, the question comes: is the through-hole filled with tin? How can I know if the welding is reliable?

We know that when the naked eye cannot see the defects inside the product, you can only choose X-ray to see through it. However, when observing the through-hole, we can only see from the side whether tin has filled the through-hole. At this time, you need an X-ray inspection system with a tilt function, such as Wellman X6800 and X8800, both of which have a 60 ° tilt function.

Industry standards and IPC clearly state that the through-hole welding rate must exceed 75%.

As shown in the figure below, we can see that each through-hole is 100% filled with tin, and only a few through-holes are not “covered” with tin. So we can confirm that the pins have been soldered firmly.

through-hole X-ray inspection OK

The through-holes in the picture below are not so good. Not only are most of the through-holes not covered with tin, but there are two through-holes with less than 75% welding rate. This may cause the components to not be fixed to the PCB and fall off easily, and also cause the two through-holes to be non-conductive and unable to achieve certain functions.

through-hole X-ray inspection NG